Our primary concern is always the safety and protection of our community and environment. To address the threat of wildfires and extreme weather, we’re expanding our maintenance programs to improve the safety and resiliency of our electric grid.

Our mitigation efforts expand upon our existing maintenance and safety programs to significantly reduce fire ignitions caused by our infrastructure while strengthening the overall electric system. Our wildfire mitigation plan is part of a larger, ongoing strategic effort to improve the safety and resiliency of our electric grid.

We’ve identified areas within our service territory that are rated by the Colorado State Forest Service as extreme or elevated fire-threat areas. In these areas, we’re conducting enhanced safety inspections of electric infrastructure with the use of infrared cameras and will begin clearing additional vegetation around equipment and structures.

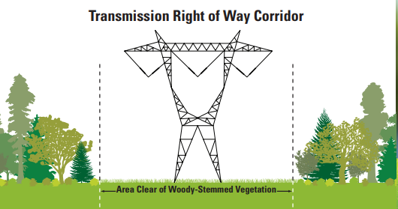

We’re looking into new ways to address the most vulnerable parts of our system, those densely forested areas where our poles need plenty of clearance space. We’ve taken aggressive action, using unmanned aerial vehicles to survey the most remote areas of our service territory and integrating those with our system maps to give us a complete picture of system deficiencies, creating reports for HCE field crews to repair.

More locally, you may see HCE crews creating a defensible space in the poles surrounding members’ homes and businesses.

When the National Weather Service issues a “Red Flag Warning” anywhere in our service territory, we will modify the operations of the electric system to reduce the chance of an electrical fire in that part of our territory. Once the “Red Flag Warning” has expired, the system will return to regular operation. This increase in fire protection also increases the possibility of more electric service outages.

Transmission line structures protection – Wrap (or spray) the lower section of power line structures with fire resistant products to provide additional wildfire protection.

Improve Vegetation Management – Remove brush from near the base of the transmission poles.

Expanded distribution maintenance – Tighten mechanical connections (hot line clamps) and conduct infrared inspections (IR).

Arc sensing technology – Firmware upgrade to expand the capability of our reclosers to detect high impedance arcing faults.

New products (trip savers and non-expulsion fuses) –Replace a number of our standard expulsion fuses in high fire risk areas.

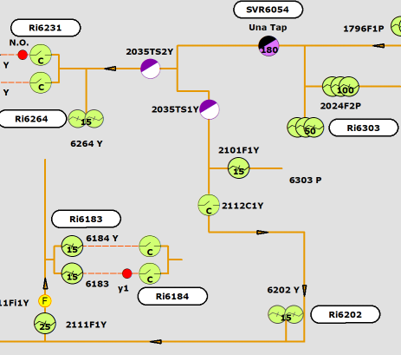

Additional SCADA controlled smart devices – Expand the use of our fire settings and re-coordination of large parts of our system.

Pano AI – The early minutes of a fire are critical, and initial response time determines the ultimate threat to lives and property. With most wildfires detected by bystanders and reported via 911, it can take hours to detect a fire, verify its exact location and size, and dispatch first responders. Pano AI allows us to receive real-time situational awareness regarding infrastructure and assets. We are performing field validation now and looking to implement in 2025.

Vegetation management – We’re currently on a five-year cut cycle to analyze and cut if necessary (typical tree growth in five years is ten feet). Dangerous or hazardous trees are removed, including dead trees at risk of falling into overhead power lines.

System inspection – We have a program to visually inspect our system every three years. Our visual inspections include the use of infrared cameras on the feeder main lines.

Pole testing – Each power pole is tested every ten years (roughly 2,100 poles every year) for structural integrity. Poles that fail testing are replaced.

Substation testing – We hire a testing and maintenance company to test all the devices at our substations every five years.

SCADA control switching points – Allows dispatchers to quickly restore power to large parts of our distribution system using SCADA from our dispatch center.

Gilman/Carbondale transmission lines – Pursuing resilience projects to provide a backup in the event of a catastrophic loss of transmission lines or major substations.

Investigate all temporary faults on main feeders – Temporary faults can sometimes turn into permanent faults, so we spend the time to patrol our main feeders for all substation trips, even when the breaker successfully re-closes.

Monthly/Annual substation inspections – We inspect our substations monthly. We also do an annual dissolved gas analysis (DGA) test for all of our substation transformers to look for increasing levels of certain gasses that can predict internal transformers issues.

Smart devices – We currently have over 70 devices in the field (reclosers and switches) that provide immediate notification of system disturbances throughout our system allowing us to quickly dispatch operations crews.

Smart meters – Provide real-time notification of system outages further narrowing down the location of system issues.

Automatic Vehicle Location (AVL) – Provides dispatchers information on the location of the operations personnel to efficiently dispatch and provide quick response.

It’s never too early to prepare. With wildfire season in mind, there are plenty of things that HCE would remind residents they can do to prepare themselves, their families and their homes, to reduce the risk of wildfire. Things like trimming shrubbery, clearing tree limbs that are close to a home, cleaning gutters, and keeping lawns mowed and watered are good first steps.

Residents should remove anything within a 15-foot radius around a powerline pole if possible and maintain unobstructed access to all HCE’s equipment, overhead and on the ground. Call HCE If anything looks amiss or concerning with HCE’s equipment.